Optimization of the packaging process

Optimization of the packaging process

Our client is a part of the international corporation. Since 2006, it has been designing and manufacturing coils, sensors, and switches for the automotive industry. The products it produces are used in passenger cars, trucks, construction machinery, agricultural machinery, and heavy equipment.

THE PROBLEM

Our client manufactures a wide range of coil types, which are packed into just a few types of packages. Each coil must go into the correctly labeled package, especially during the preparation of shipments. Otherwise, despite the lack of downtime in production, the consequences are twofold: first, a negative impact on the company's image due to incorrect product packaging, and second, additional costs associated with correcting the error by re-shipping the product.

These costs can be disproportionate to the product's value, especially when the error occurs in a remote part of the world.

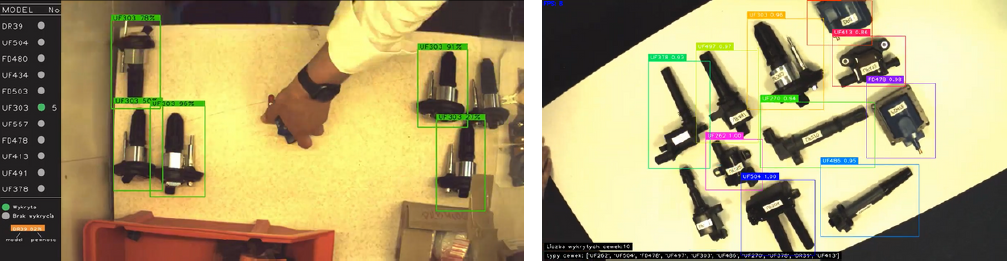

The use of cameras at the stations along with an intelligent type recognition system.

Pairing of a given coil type with the appropriate package.

Collecting data from the packing stations for the first three months - for this purpose cameras were used, and their installation was modified many times to provide the most accurate data and meet security requirements (e.g., GDPR).

Proof of Concept - that is proof created in the fourth month that the solution is feasible in practice.